solution

Solutions

Semiconductor/AMHS Solutions

At its core, the system focuses on precise control, smart coordination, and high flexibility. It uses smart scheduling algorithms to keep operations stable and efficient, and a modular design that allows easy adjustment and future expansion, creating a reliable and scalable logistics solution for advanced manufacturing.

Key Features

-

Precise control to create a stable manufacturing process

Algorithm-driven material handling scheduling enables precise path and node control, reducing variability and ensuring stable process rhythm. -

Intelligent collaboration enhances overall system efficiency.

Multiple modules automatically collaborate through real-time data exchange to achieve load balancing, path optimization, and maximize equipment utilization. -

Flexible scaling, supporting highly modular deployment

It adopts a modular architecture and variable topology design, which can be quickly adjusted with production line updates to support long-term expansion and upgrade needs.

Intelligent scheduling creates a highly efficient and seamless production process.

AMHS integrates key equipment through precise scheduling and real-time collaboration, enabling wafers to flow stably and smoothly automatically between various processes. The system adopts a scalable modular design, which can be quickly adjusted according to production line needs, improving overall operational efficiency and helping wafer fabs establish a reliable and flexible automated handling environment.

System Process

-

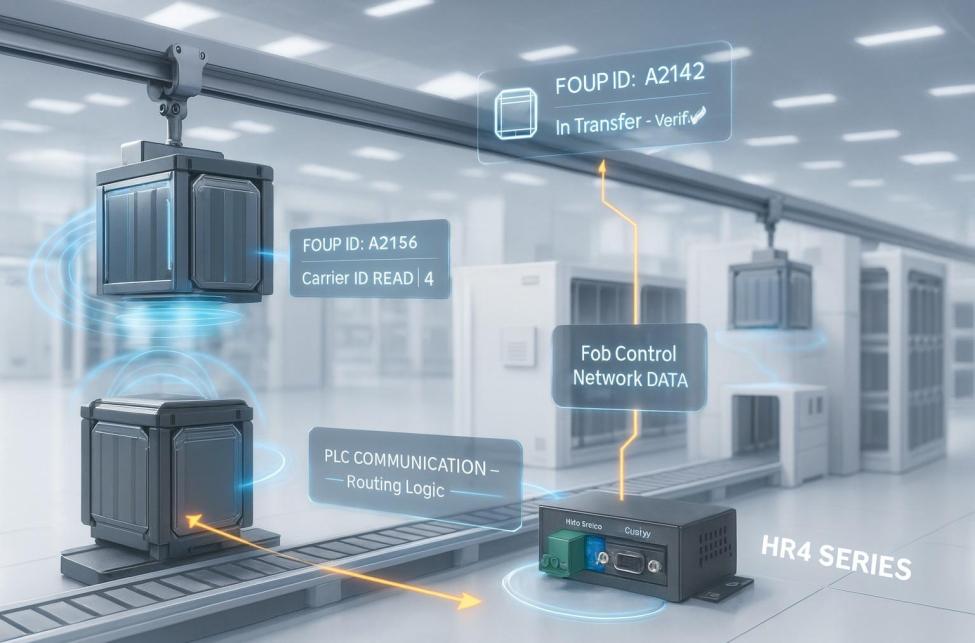

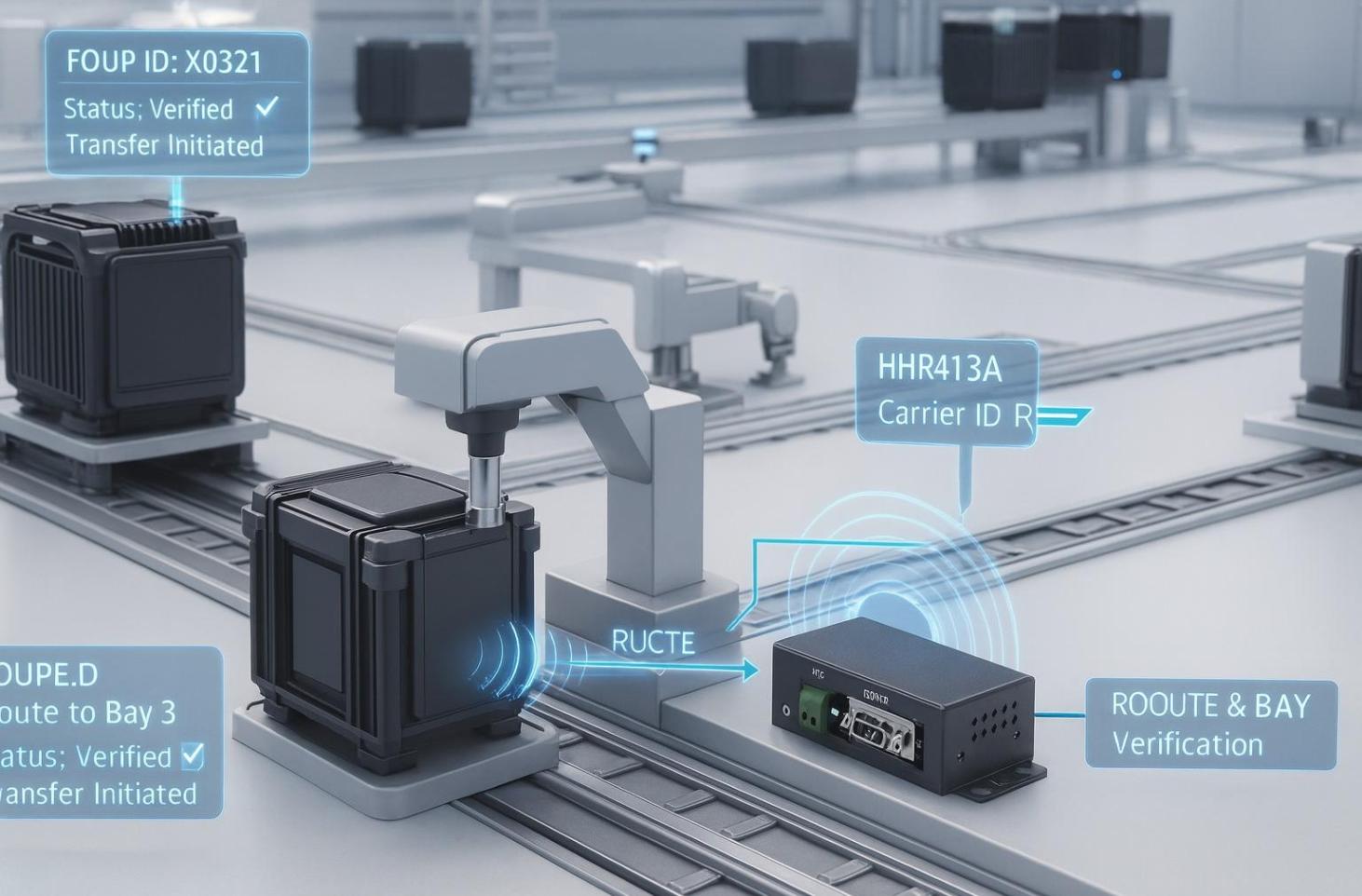

AMHS (Automated Material Handling Systems) — FOUP Identification and Tracking

Real-time FOUP RFID identification for error-free AMHS routing and full fab traceability. -

Process Equipment / Front-End Tools — FOUP Verification and Process Control

Precision FOUP identification and lot traceability engineered for advanced semiconductor tools.

-

Wafer Sorting and Transfer Systems — FOUP Identification for Inter-Bay and Intra-Bay Movement

Error-free FOUP routing and traceability for wafer sorting and transfer systems. -

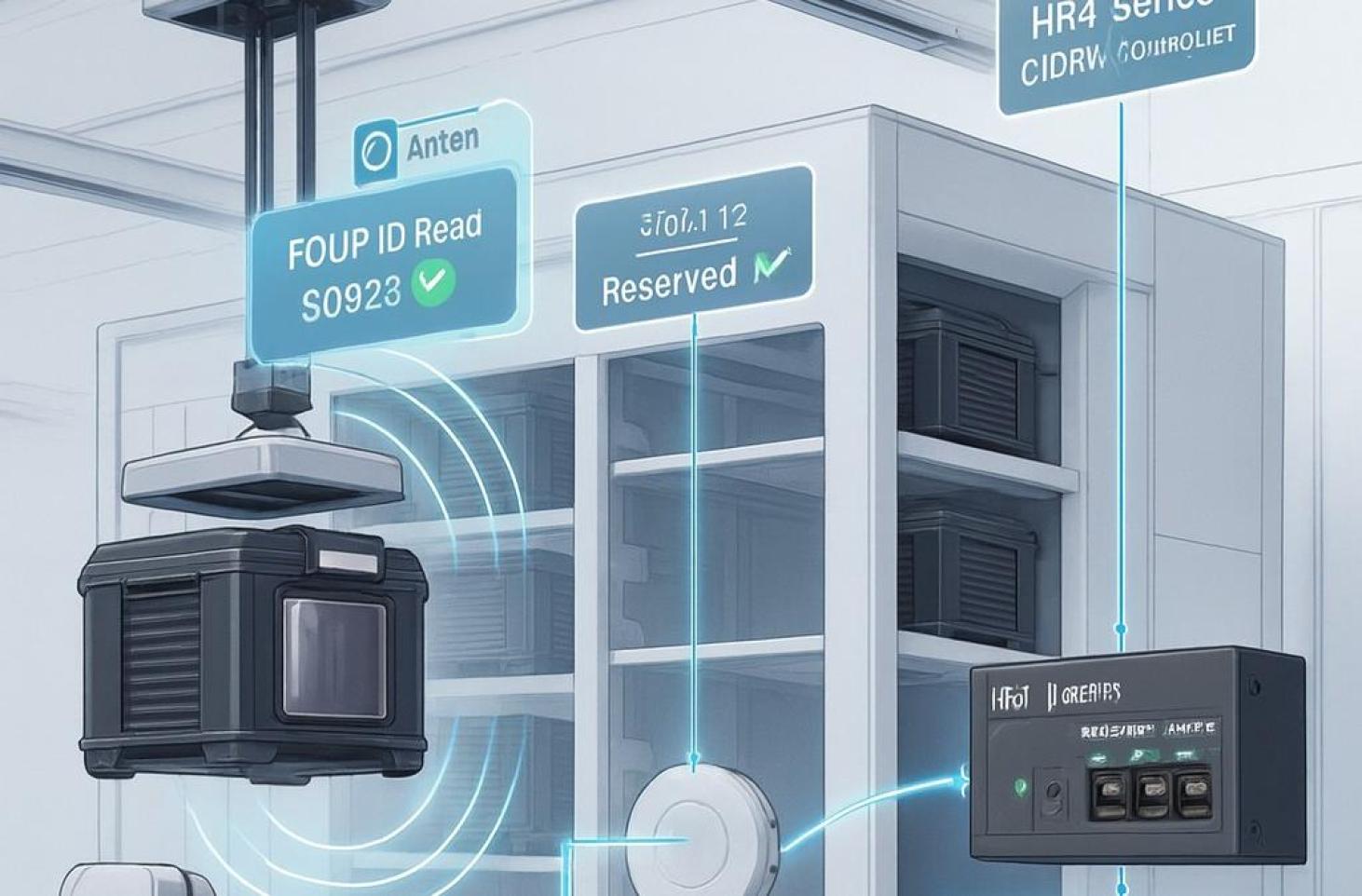

Stockers and Overhead Hoist Transport (OHT) Systems — Carrier Verification and Routing Control

Real-time FOUP RFID verification for accurate stocker and OHT transport operations.

-

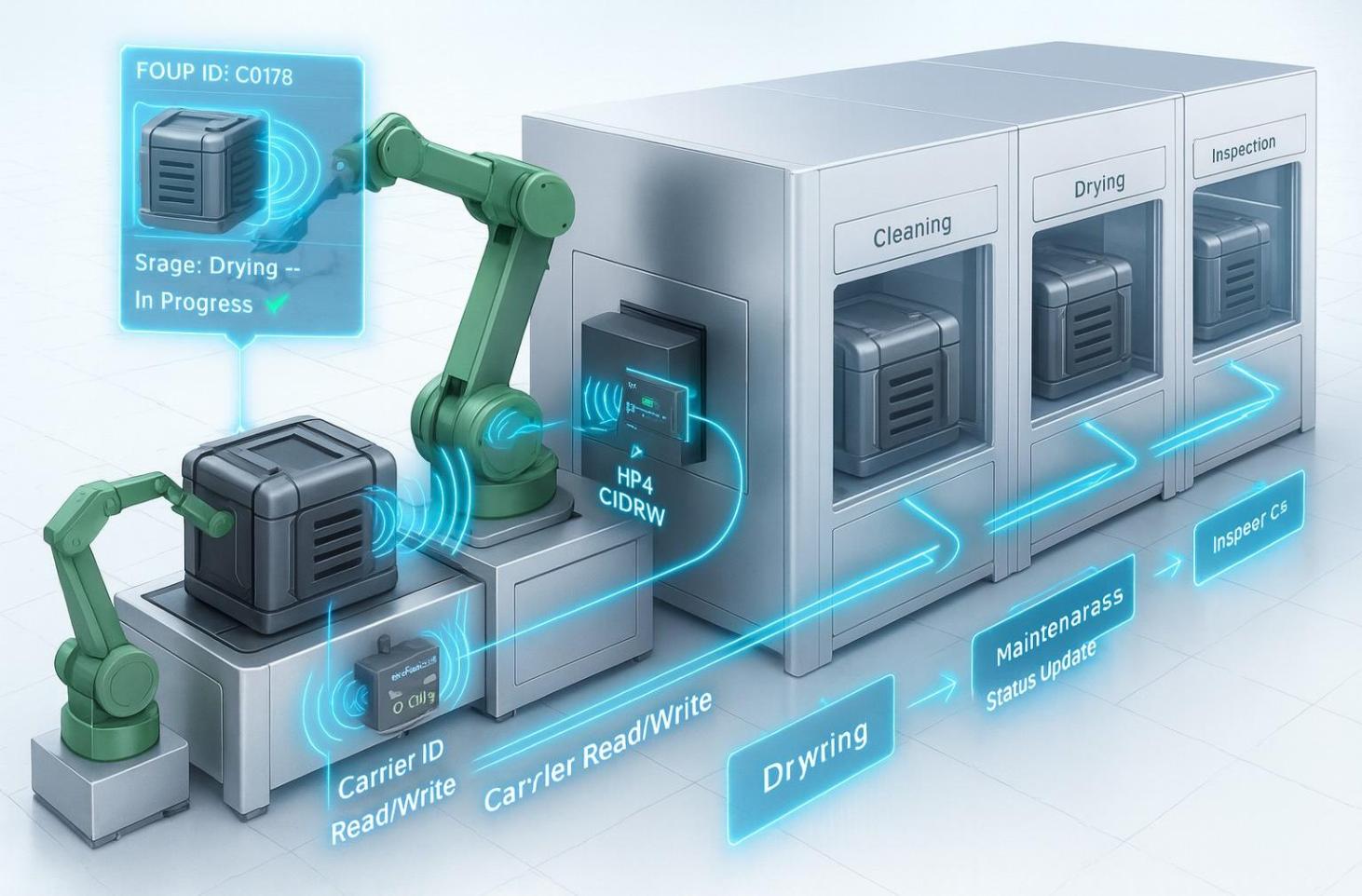

Carrier Cleaning and Maintenance Systems — FOUP Tracking and Traceability

RFID-based FOUP maintenance tracking ensures cleanliness validation and full traceability. -

FOUP Management & Logistics Stations — Carrier Tracking and Dispatch Verification

Ensure accurate FOUP dispatch and routing with real-time RFID verification at fab logistics stations.